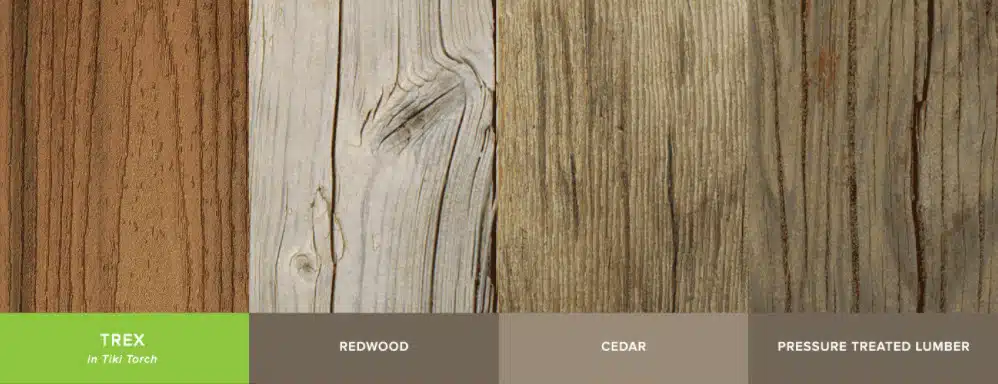

When it comes to adding a deck to your home, you have multiple options to use for your “decking” material, or the top visible layer of a deck. Composite and wooden decks remain the two most popular options, but which is “better”? Which should you have installed for your new deck?

Composite vs Wood Decking

Early generation composites for decking first came on the market in the 1990s, originally introduced by today’s largest composite manufacturer – Trex. Composite decking is made from 95% recycled material: left over wood fiber from lumber manufacturing (primarily sawdust from furniture, flooring and cabinet manufacturing) and recycled plastics (primarily recycled plastic shopping bags) are mixed together, pressed, and then extruded into decking boards and railings. (I’ve personally seen this process at Trex’s headquarters in Virginia, it’s quite remarkable!)

While these earlier pre-2010 versions of composite decking had many advantages over wood decking, they were still prone to fading, staining, and molding over time, just like their wooden counterparts. These earlier generations of composite decking also required annual maintenance – deep cleaning, painting or staining, and structure maintenance – in order to keep the deck safe, retain color, and ward off mold and mildew. The surface was also soft enough to scratch when moving deck furniture around or from energetic play by kids and pets.

In 2010, Trex became one of the original manufacturers of capped composite decking. Many manufacturers followed suit by capping their composite boards, while the majority of un-capped composite boards have now been discontinued. By applying a long-lasting and extremely hard coating to the surfaces of the planks, the boards now don’t fade, stain or mold, grain patterns are retained, and the decking does not split, develop cracks nor splinter.

What about Wood?

When first installed, traditional wooden decking looks great with its rich colors and natural grain patterns. But as anyone who has an all-wood deck can tell you, wooden decking does not retain its initial beauty for long.

Wooden decking requires yearly maintenance (hours of sanding, staining and painting) to prevent the surface from turning to a grey and unattractive color, no matter what species of wood is used. The grain patterns also fade over time, turning into cracks and hazardous splinters, an especially dangerous condition if there are children who play on the deck or if you ever want to walk on your deck in bare feet. In order to retain the color and grain patterns, and to prevent splintering in wooden decking, homeowners have to perform yearly pressure washing, followed by an application of stain or sealer. Even with these treatments, problems often develop over time.

Wood is also susceptible to rot, termite infestation, and ultimately wear of the decking boards in heavily traffic areas. This leads to expensive and time-consuming inconvenience of repairing or replacing worn and damaged deck boards. And as individual deck boards are replaced, the color of the new boards will not match the rest of the deck.

An unmaintained wooden deck can become a safety hazard and an eyesore only a few years after it is built. Wood ends will start to curl up and nails will begin to pop out creating an uneven and unsafe structure.

Building a wooden deck also requires cutting down fresh trees, contributing to deforestation and creating ecological damage, affecting the wildlife dependent on these forested environments for their survival.

An Eco-Friendly, Low Maintenance Alternative

Capped composite decking, with its durable capped surface, is a breakthrough alternative to both all-wood decks and earlier generations of composite decking. Utilizing this revolutionary new product also helps the environment – Trex alone saves 400 million pounds of plastic and wood from landfills each year.

A single 500 square foot capped composite Trex deck, for example, contains 140,000 old recycled plastic grocery bags! This puts Trex decking among the biggest recyclers of plastic bags in the U.S.

The manufacturing process of composite decking is also engineered for maximum recycling of industrial waste as almost all byproducts are reused within the factory itself. Ecologically damaging chemicals are kept out of the production process, resulting in low levels of waste, energy use, and a small CO2 footprint. Trex has never cut down a single tree to manufacture its decking boards.

The surface capping on the new generation of Trex composite products is exceptionally hard and durable, resulting in a finished deck which can hold up to years of summer sun, freezing winters, and heavy-duty family use. There is no maintenance needed on these decks beyond sweeping away fallen leaves with a broom and an occasional rinse with the garden hose to clean-up spills and other messes.

The Lifespan of Capped Composite vs Wood Decking

The lifespan of an all-wood deck varies according to several factors, including:

- The species of wood used (Ipe being the strongest wood, and one of the only types of wood we suggest and install for an all-wood deck)

- Ventilation under the deck and how close the deck is to the ground

- How much sun or shade the deck receives

- Whether or not the deck surface is stained, sealed, or painted

- The quality and grade of the wood used

For a well-maintained, all-wood deck, useful lifespans ranges from as low as 8 years and up to 20 years or more. However, longer lifespans for wooden decks are only achieved with regular maintenance.

By comparison, high-performance Trex composite decking has a lifespan of at least 25 years, guaranteed by the manufacturer. In reality, a new-generation capped composite Trex deck may have a lifetime of as much as 30 to 40 years.

Even more importantly, achieving this long life span does not require the investment of time and money for yearly maintenance, and the need for replacing individual deck boards due to wear or breakage is virtually eliminated.

Other Benefits of a Capped Composite Deck

Hundreds of matching or complimentary deck railings, stairs, trellises, and pergolas are available to chose from – all also made from composite materials, extending their life to last as long as the deck itself.

There is also a wide selection of colors and grain patterns to choose from when building a capped composite deck. Deck boards can be laid-out in pleasing geometric designs, adding an extra dimension of visual appeal to the finished deck.

While the initial cost of a composite deck is slightly more than an all-wood deck, the time and maintenance costs required for a wood deck actually exceeds that of the initial cost of a composite deck within just 3 years, making composite decking the best bang for your buck.

Custom Deck Creations is an exclusive builder of custom decks in Michigan, using the newest generation of capped composite products, including Trex and TimberTech. Call us today for a free design and a free quote for your new deck.